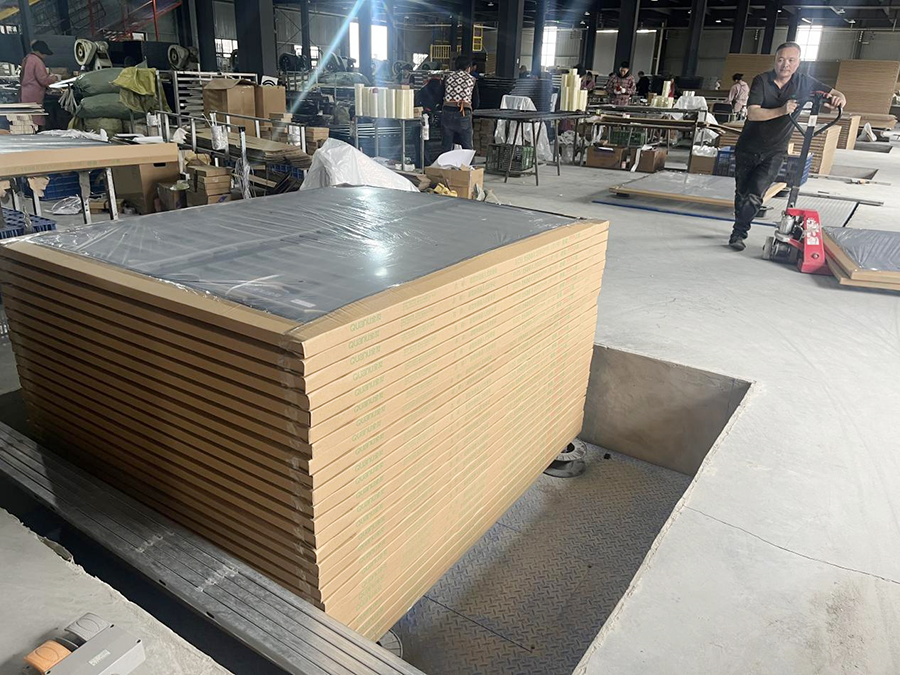

In pursuit of excellent production efficiency and quality improvement, our company implemented a key upgrade of the packaging workshop in November 2024 - introducing 6 advanced packaging lifts. This move has brought all-round optimization and innovation to the packaging operation.

In terms of efficiency, these lifts greatly speed up the packaging process. By quickly and accurately lifting the goods to a height that is easy to operate, workers do not need to bend down frequently and carry them laboriously, and the packaging time is greatly shortened. Taking the e-commerce warehouse operation scene as an example, the originally cumbersome packaging process has been efficiently simplified, and the turnover speed of goods has been significantly accelerated, providing strong support for the efficient operation of the business.

In terms of labor intensity, the automatic lifting function has become a "burden-reducing artifact" for workers. Especially when carrying heavier goods, it effectively reduces the risk of physical injury caused by long-term repetitive labor, allowing workers to say goodbye to overwork and create a more comfortable and healthy working environment for them.

The packaging lift also shows strong adaptability. Its lifting height can be flexibly adjusted according to actual needs, whether it is facing packaging equipment of different specifications or the stacking height of various goods, it can be easily adapted. In industries such as food and daily chemicals that have diverse requirements for production lines, it perfectly matches the packaging requirements of different production lines to ensure smooth production.

Safety assurance has always been our focus. These lifting platforms are equipped with basic safety devices such as anti-slip tables and guardrails to effectively prevent goods from slipping and people from falling. Some equipment also has emergency braking and overload protection functions, which adds double insurance to operational safety and avoids safety accidents to the greatest extent.

In terms of space utilization, the packaging lifting platform also performs well. Its structural design is compact and occupies a small area, and the foldable and movable style can be easily stored when not in use, without taking up too much storage and production space, providing more flexibility for workshop space planning.

From the perspective of packaging quality, the stable lifting platform provides stable support for the packaging process, effectively reduces the shaking and collision of goods during the packaging process, makes the packaging more solid and beautiful, and thus improves the overall quality image of the product, adding points to the company's brand image.

The upgrade of the packaging workshop is an important step for the company to optimize production and enhance competitiveness, and injects new vitality into the company's sustainable development.